In the wax industry the terms wax emulsions and wax dispersions can be confusing in many instances. We define a wax dispersion as micronized wax dispersed in water or solvents by means of high shear mixing in the presence of surfactants for the use in the ink and coating industry mainly.

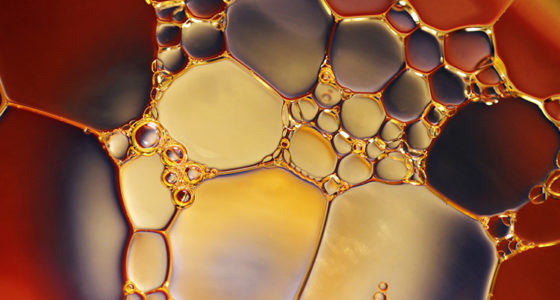

We define wax emulsions as products produced from wax in the molten stage blended with water and surfactant to form an emulsion. On cooling to room temperature the wax droplets solidify to form a stable wax in water emulsion which is according to definition also a dispersion but referred to in industry as wax emulsions.

Wax emulsions can vary in wax content from 1% to 60% where the wax can be oxidised hard wax, natural wax or paraffin type waxes. Depending on the surfactants used these emulsions can be either non-ionic, cationic or anionic. The choice normally depends on the application and the products the wax emulsion needs to be blend with. The pH of the blend will in most cases determine the choice. Wax emulsions are used in applications such as construction board, liquid polishes, coatings, mould release agents and concrete curing, to name a few.

Another common use of wax emulsions are paste floor polishes. In this instance the emulsion is a water in oil emulsion where the outer oil phase is a combination of a wax blend and solvent. Cerax specialise in the manufacturing of a one pack solution for this industry.